The Vapothermal Carbonization (VTC)

Vapothermal Carbonization (VTC) is a process that has been developed from Hydrothermal Carbonization (HTC), which uses heat and pressure to imitate the natural coalification process (the formation of fossil coal over a period of millions of years) in a much shorter time.

In contrast to the HTC, the reaction does not take place in a hot water bath (hydro = water, thermal = caused by heat) but in a reaction atmosphere of saturated steam (vapo (r) = steam, thermal = caused by heat).

The VTC is a batch process, the reaction time is typically three to four hours, depending on the biomass, reaction pressure and temperature in our plants, in order to produce biochar with a degree of carbonization and a calorific value between lignite and hard coal.

The advantage of VTC compared to HTC lies in the simpler process management, the considerably higher throughput and significantly lower requirements for the pretreatment of the biomass to be treated.

Biomass that is to be treated with VTC does not have to be reduced to a pumpable size, as with the HTC, but can in most cases be used without any pretreatment at all. This leads to considerably lower investment costs for a Vapothermal Carbonization plant.

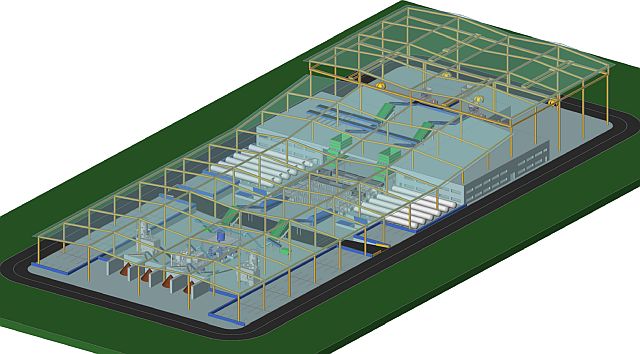

The following picture shows an exemplary plant for the production of biochar from 3,000 m³/d of organic fraction from household waste: